Results 281 to 290 of 1418

-

-

-

April 20th, 2007 09:57 AM #283

fyi

sources:

http://biz.balita.ph/html/article.php?story=20070418154747807

http://sg.biz.yahoo.com/070418/16/47wla.html

18 - Auto parts makers back comeback of electric cars

18 - Auto parts makers back comeback of electric cars

Wednesday, April 18 2007 * 03:47 PM BST

Business The local auto parts makers comprising the Motor Vehicle Parts Manufacturers Association of the Philippines (MVPMAP) has signified its support for the Philippine Electric Vehicle (PEV) Program.

The PEV Program aims to introduce a clean, sustainable and affordable urban mass transport service on a limited travel distance.

According to Dir. Ferdi Raquelsantos, head of MVPMAP's own Philippine Utility Vehicle Program (PhUV), "the PEV is much like our own PhUV as it can transport both cargoes and passengers, though the PEV can operate only on a limited and confined range. It currently has a local content of around 50 percent thus we think that MVPMAP could help increase this to over 70 percent."

An electric vehicle (EV) is a motor vehicle powered by an electric motor and an on-board source of electricity, normally a battery pack.

Its advantages over a conventional internal combustion engine fueled by gasoline are that it consumes power only when in motion, emits no fumes and is very quiet even as it runs, thus there is no wasted fuel in traffic, no air pollution and no noise.

EVs far outnumbered gasoline vehicles at the turn of the 20th century. However, with the continued improvements in the gasoline engines and the availability (then) of inexpensive gasoline, EVs became extinct in the 1920s.

It is only now that it is slowly making a comeback as car manufacturers are coming up with the more expensive hybrid cars, powered by a computer-controlled engine that runs on both electricity and gasoline. Foremost among this is the Toyota Prius.

Many Filipinos may be familiar with the EV in the form of the electric golf carts seen in golf courses and even the bump cars in the amusement centers of some malls.

The downside of an EV is that in current models, a four-hour full charge on conventional 220 volts home outlet costs about P1,500 and can travel only 80 kms. This translates into about P18.75 per km. compared to less than P5.00 per km. for gasoline-fed cars.

"This is another challenge that the PEV proponents will have to address – make the EV comparable to the gasoline-fed cars in terms of operating cost per km. before we could mass produce them", said Raquelsantos.

Romeo Morave, president of Electromotion Motor Corporation and at the forefront of pushing for the PEV, said they are currently studying using a battery pack being developed in the USA that will increase the range of the EV to 200 to 300 miles (320 to 480 kms.).

"We are also looking at cheaper alternative 'refueling' schemes such as photovoltaic arrays or solar cells. We are at the same time studying the regenerative braking system in an EV that turns the electric motor into a generator when the brakes are applied, thus recharging the batteries during deceleration," he said.

"Currently, we have a PEV that sits 10 passengers, carries a payload of over 1,200 pounds and runs at a maximum of about 65 kms per hour", Morave said.

The PEV is now being pilot tested by the Philippine Economic Zone Authority within its Cavite Export Processing Zone to transport some 90,000 workers daily within the zone.

The vehicle's co-inventor, Roel Judilla, former dean of mechanical engineering at the Mapua Institute of Technology, said the current PEV costs around P600,000 but he said they are currently working to bring this down to about P300,000 to P400,000 with the application of more local parts from MVPMAP members. It has an AUV body supplied by Francisco Motors, one of MVPMAP's partners in its PhUV Program.

"To avoid the exorbitant electricity costs, we are developing a model that would run using solar energy. But at the moment, we are marketing the PEV for specific short distances such as inside the ecozones, military camps, subdivisions, theme and leisure parks, golf courses and resorts", he said.

MVPMAP is currently evaluating the possibility of including the PEV in its PhUV Program so that PEV manufacturers, parts makers and buyers can also avail of the package of incentives being finalized by the Board of Investments for the PhUV Program. This will hopefully make the PEV affordable to own and feasible to operate.(PNA)

-

April 20th, 2007 10:39 AM #284

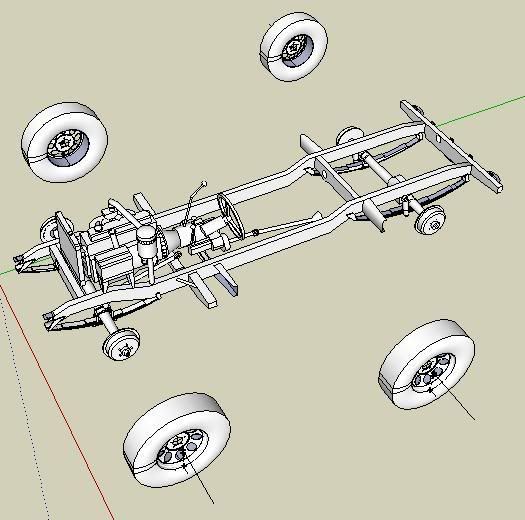

Excellent 3D work of the chassis, OyiL!

About the components chosen: Leaf springs, solid axle and drum brakes for the front? I would prefer coil springs, independent suspension and disc brakes at the front. But who makes the final decision about these things?

About the process: Has anybody done a 2D CAD technical drawing based on the components chosen? If nobody has, shouldn't 3D drawings be based on the technical drawings?

-

April 20th, 2007 12:47 PM #285

components:

i am in-line with your thinking. independent double wishbone is the desired suspension type for the front. the whole group decides on the components based on some factors, e.g budget, specifications.....etc.

CAD:

Yes 3D drawings should be based on the technical drawings. We should get it from the manufacturers - they should give it for free.

My 3D is just for the body styling design. The wheels and tires on that 3D is accurate - 215/85R16 tires on 16x7 5 spoke pcd 4.5" 0 offset 3.3" centerbore wheels. The wheelbase is also accurate - 3050mm.

Track width and min ground clearance should be based on the axles to be used so:

assumed a overall width=1800mm

tire width = 215mm

wheel offset = 0

then:

max track width = 1800 - 215 = 1585 ( DMAX is 1520, INNOVA is 1510, REVO is 1445) have to find which available brand new part(axles f/r) would satisfy the design.

I have the proposed engine dimensions including assumed matching transmission dimensions. To make sure that the size of the engine bay is good on 3D. I need windshield measurements. and frame measurements to be as accurate as possible. - to 3D my body shell design

-

BANNED BANNED BANNED

BANNED BANNED BANNED

- Join Date

- Oct 2002

- Posts

- 3,790

April 20th, 2007 10:55 PM #286why not take the jeepney favorite axle...yung pang elf... baka mas mura yun kung "surplus" ang sourcing....and can accomodate big diameter tires....bagay din sa all leaf-spring suspension.

maganda rin sana kung LSD na rear differential ang available...

-

April 20th, 2007 11:49 PM #287

Hi donbuggy.

(1) The final decision is made by the market, ie, demand and price. If we're going to put out a PhUV that will price lower than 350K, then perhaps we should work with the assumption that the production cost should not exceed 280K. Otherwise the subsequent enterprise might not be viable at all.

This is the amount we as designers need to apportion into three parts: Rolling Chassis, Power Train, and Body. Basically, you want your rolling chassis to handle the load and the road; your power train to have adequate 'pull' and response; and your body to provide comfort and enticement.

If there exists an independent suspension system that can handle the hyperloaded rural offroading that jeepneys are famous for, and still fit into the budget, then we can use it -- why not?

How would you allocate your production budget (see attached)? Note that as your underchassis cost rises, you deprive the other two of funds. So, you see, the sky is actually not the limit for PhUV. Bottomline: If PhUV is not marketable at an OPTIMUM LOW price, it will be dead in the water.

(2) In answer to your question on process, AFAIK, in the real world of automaking, the 2D technical drawings (via "computer-aided drafting") are firmed up AFTER the styling is done and modeled mathematically and in clay. In other words, the 2D CAD comes just before the CAM, and all of that comes after stylists give the go signal. (Note that the reverse is true for architectural design & construction).

This design roundtable started designing the PhUV from outside-in. Now that the time has come to design from inside-out, our handicap is that we do not have a satisfactory spec-database of existing parts and components to firm up our design decisions. It seems MVPMAP members are not that keen yet on supplying auto design teams like ours with their product specs. That's because they are either multinationals or totally beholden to the bigboys they supply. That's just for technical specs. The other thing we need is the prices of parts and components.

If you can find it on the web, then fine. But there's nothing like getting out, hunting for the parts, digging for technical data, and taking actual measurements. You will find them in REPLACEMENT parts suppliers (and SURPLASAN, if you care to).

In the case of my personal FUV prototype (Chokaran), it took me just a couple of months designing but nine months running around looking for the appropriate parts that would match the drawings. This PhUV design project (and others like it) is not like architectural design, where nagkakandarapa ang mga supplier sumipsip sa arkitekto para lang mai-specify yung produkto nila. Hindi pa kasi tanggap sa Pinas yung idea of an independent auto design studio -- which is what this little group is evolving into, little by little.

dprox

www.disenyopilipino.ph

-

-

-

As expected, in response to Tesla’s entry into the Philippines market, Ford will be bringing in the...

Tesla Philippines