Results 31 to 40 of 57

-

September 26th, 2009 04:33 PM #31

I agree with the idea that jeepneys should be replaced. Jeepney maker pioneers like Francisco Motor Corporation must come up with new ideas now that they have found a new partner In GW motors. They can bring back the days when they produce vehicles of Mazda and their own AUV Anfra using Mazda parts.

They can start anew by coming up with a jeepney replacement and other vehicles using GW technology like the following....[SIZE=3]The FMC Assembly Plant is currently being converted to assemble Semi Knocked Down (SKD) Great Wall Motor Vehicles. [/SIZE] You can see details at http://elmerfrancisco.com/greatwall.

Great Wall Sailor

Great Wall Florid

Great Wall PeriLast edited by jpdm; September 26th, 2009 at 04:39 PM.

-

September 27th, 2009 07:20 AM #32

I saw this old beat up Anfra yesterday somewhere in Cavite...

Originally posted by Oyil

Its a must for FMC to redesign and improve the Anfra in make it acceptable for todays motorists.

-

September 27th, 2009 09:35 AM #33

-

October 2nd, 2009 10:05 PM #34

A recent article about FMC...

[SIZE=2] [/SIZE][SIZE=3]Of Cars and Finger-pointing[/SIZE]

Romeo Y. Lim

Malaya

October 2, 2009

Editorial

I AM very much tempted to do some finger-pointing and start my barrage of choice swear words against the incompetence that we all witnessed at the height of "Ondoy."

But I bite my lip because I know how hard it is to be competent when many of our government agencies lack the wherewithal to conduct such operations. It is an oversimplification of the budget process but if you can afford to enjoy million-peso dinners and hundreds of thousands of pesos on one meal, how come they can’t give our Philippine Navy more upgraded rubber boats which they have been asking for since time immemorial.

So despite the temptation to blame someone or somebody, I will talk of the tale of two car industries.

Perhaps if we can’t get our act together on dealing with calamities, maybe we can find a way to help revive/build an industry that will open more job opportunities for our people.

Some years back, the Philippines had an upbeat automotive assembly industry.

Trucks and jeeps were being assembled by independently owned workshops and factories in the country. Most successful among these was [SIZE=3]Francisco Motors Corporation (FMC)[/SIZE]. Incorporated in 1960, it started as a small painting shop in 1947 which later became a factory for the building of jeepney and truck bodies.

A flourishing venture then, it entered into partnership with foreign companies such as Ford and Thames , then later with Isuzu, Mitsubishi, and Mazda. FMC became the largest assembler of local motor vehicles in the country and had 2,000 under its employ and producing 5,000 sturdy and roadworthy units annually.

However, the industry, notably FMC, was severely hit by the Asian financial crisis of 1997. It eventually lost steam because it was heavily dependent on imported parts, from simple screws to engine blocks, made in foreign countries.

While it successfully served the domestic market for a while, it had not much of a shield to protect itself from the juggernaut of globalization.

The peso plunged, the cost of imports rose, and the country was swamped by tariff-free second-hand vehicles from Korea and Japan. Coupled with the arrival of "surplus" vehicles, was the free entry of completely built-up (CBU) vehicles.

Eventually, the tragedy that descended on local automotive manufacturing could be traced to the failure of state policies to protect and promote local industries.

In contrast, consider the story of Proton, an auto manufacturing company in Malaysia. Like FMC, it entered into partnership with foreign car manufacturers. However, the basic difference with FMC is that Proton consciously developed towards self-reliance. When Proton started making cars in 1985, all the components were manufactured by Mitsubishi but, through government support, local parts were gradually made as technologies were transferred and skills were gained.

By 1989, or in a matter of four years, Proton was weaned from its dependence on Mitsubishi as it produced the 100,000th Proton Saga.

Malaysia did not ban the importation of Japanese cars but it saw to it that Proton would be protected by imposing tariffs on imported cars while giving incentives to its local customers by granting handsome rebates. With globalist pressures, tariffs of imported cars to Malaysia were gradually reduced but then Proton had already comfortably established its foothold in the local market.

It developed global competitiveness in the area of car manufacturing because it took pains to develop its muscle by protecting local initiatives from undue outside competition.

This has been repeated in the experiences of other countries that have grown strong because they chose to rely on themselves and protect their resources rather than entrust their destiny to others.

Can’t we do this?

[SIZE=2][SIZE=2] [/SIZE]Email address: colonelromeolim*yahoo.com[/SIZE]

-

-

October 29th, 2009 07:59 AM #36

-

October 30th, 2009 08:40 PM #37

My god, what tire size is on that thing, That does not look to safe for a vehicle that size.

Looks like trailer tires.

Looks like trailer tires.

-

October 30th, 2009 09:32 PM #38

Those would be the typical tire sizes for commercial vans here in Asia. Not great for handling, but not as bad as you might think.

Ang pagbalik ng comeback...

-

November 6th, 2009 10:03 AM #39

http://www.flickr.com/photos/7746504*N04/

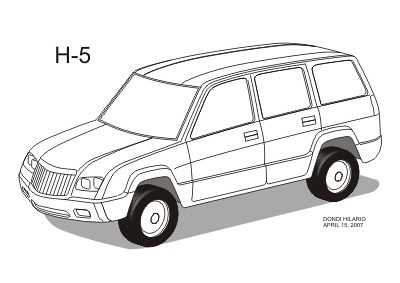

I hope the future of Anfra will look like this..

-

Verified Tsikot Member

Verified Tsikot Member

- Join Date

- May 2008

- Posts

- 99

December 21st, 2009 11:51 AM #40

Reply With Quote

Reply With Quote